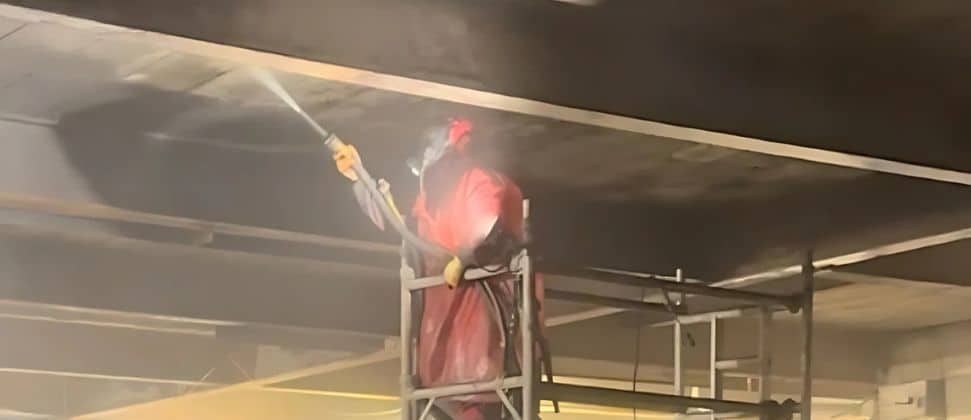

Welcome to the latest piece of Quill Falcon wizardry… the Vapour Reduction System (VRS). This clever innovation is designed to be compact and lightweight while tackling some of the more prominent challenges in Quill blasting.

Design excellence

At the core of the VRS is a smartly engineered water separator that removes surplus moisture from the blast hose before it even reaches the nozzle. The result is a significantly drier blast, making it ideal for tight or enclosed spaces where misting can be a serious issue.

Asbestos or lead removal in confined spaces

The VRS is especially valuable for customers or contractors working in asbestos or lead removal, or for anyone needing to blast in confined environments. During testing, the system was shown to remove up to four litres of water per hour under average machine settings — a remarkable improvement that has a ripple effect across the entire blasting process.

Smarter blasting with the Vapour Reduction System

With less water in the mix, the blasting media stays drier, which makes cleanup much easier and quicker. Visibility inside the enclosure is also greatly improved, creating a safer and more efficient working environment for operatives. In addition, the reduced moisture means that contaminated grit is lighter and therefore cheaper to dispose of; a significant cost-saving benefit for hazardous material projects.

The VRS also helps to speed up the job itself. Operatives no longer need to pause and wait for mist to clear, allowing for a smoother, more continuous workflow. And because less vapour is being drawn through the system, HEPA filters are better protected from moisture damage, prolonging the lifespan of Negative Pressure Units (NPUs).

In short, the Vapour Reduction System is a compact, powerful and easily manoeuvrable solution that enhances safety, efficiency, and cost-effectiveness in blasting operations. Whether you’re working in a sensitive environment or simply want to improve your workflow, the VRS is a smart investment that delivers real results.

But you don’t have to take our word for it. Here’s what our customers have to say about it:

“[The VRS] reduced the amount of water on the enclosure floor, making the clean up process much easier and quicker. The reduction of vapour in the enclosure provided better visibility, allowing increased blasting periods, reducing the overall project time.” M Hearson (Contracts Manager)

“The VRS provided exceptional visibility when used in small confined areas, we will be using the VRS on every project going forward.” L.Duffy (Supervisor)

Want more details about hiring or buying the Vapour Reduction System? Get in touch with our team.